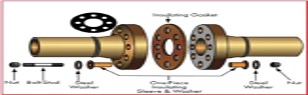

Insulation kit

Insulation kits are designed to prevent galvanic corrosion between flanges of dissimilar metals, for example a carbon steel flange bolted to a stainless steel flange. A conducting liquid such as water must be present between the two flanges for galvanic corrosion to occur. On oil and dry gas duties, insulating gaskets ARE NOT required.

Type of Insulation Kit

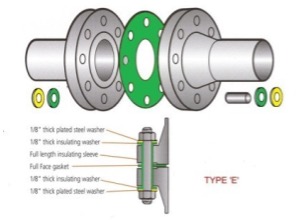

FULL FACE TYPE (TYPE E) – This gasket kit provides complete protection of both flanges. The gasket has the same outer diameter as the flanges. This feature will prevent the collection of foreign matter between the flange faces to ensure complete cathodic isolation.

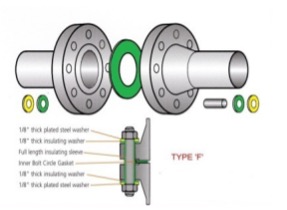

RAISED FACE TYPE – (TYPE F) This gasket is manufactured to fit only the raised face surface of the flanges. The outside diameter of the gasket is designed to be slightly less than the inside diameter of the bolt circle. We do recommend the flanges be wrapped to prevent foreign material from “shorting out” the flanges.

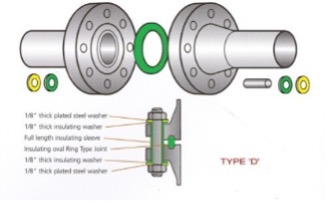

RTJ TYPE– (TYPE D) Are made for tongue and grove flanges and dropped into the grove. Typically manufactured to API 6A for wellhead equipment. They also comply with ASME B16.20 sizes and ratings.

If used, the insulation kit will consist of the following:

- insulating gasket;

- insulating sleeves to be placed around the stud bolts;

- insulating washers and steel washers.

Note: The conditions that cause galvanic corrosion (two dissimilar metals brought into contact with a conducting medium) must be guarded against. Uncoated carbon steel stud bolts used on stainless steel flanges in a wet environment, and carbon steel pipework screwed into brass gate valves on water duties, are two examples of “galvanic cells” which can easily be avoided.

- Nominal Pipe Size and Pipe Schedule: Must always be specified. Insulating gaskets, unlike CAF gaskets, are an exact fit, from the OD to the ID of the flange.

- Flange Pressure Class: Always to be specified.

- Style of Insulating Kit: Full face or inside bolt location. RTJ gasket insulating sets are not used on many projects.

- Gasket Material: Usually phenolic laminate or neoprene faced phenolic laminate.