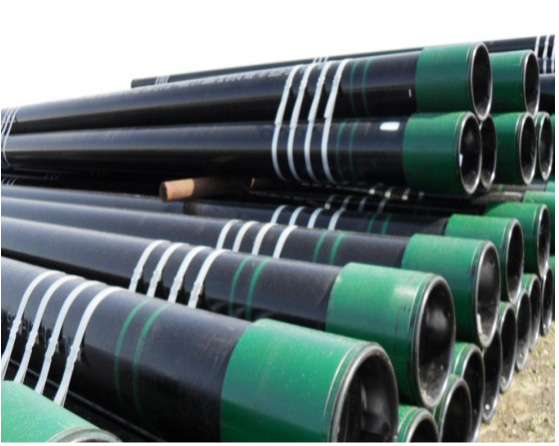

Casing & tubeing

Casing and tubing are the main parts of the well construction. All wells drilled for the purpose of oil or gas production (or injecting materials into underground formations) must be cased with material with sufficient strength and functionality.

CASING is the major structural part of a well. It is widely used for fastening oil and gas well wall or bore hold, with bigger diameter than tubing pipe, including surface casings, technical casings and oil layer casings. In practice, to prevent the wellbore from collapsing, a steel pipe should be installed and cemented in the wellbore. It can maintain borehole stability, prevent possible contamination of water sands, isolate water from producing formations and control well pressures during drilling, production, and operations.

TUBING basically means a tube running inside casing and serves as a channel through which oil and gas is produced. It must be adequately strong enough to resist loads and deformations associated with production and workovers. It should also be sized to support the expected rates of production of oil and gas. If the tube is too small, it would restrict production and subsequent economic performance of the well. If too large, however, it will have an economic impact beyond the cost of the tubing string itself, because the tubing size will influence the overall casing design of the well

API 5CT casing pipes with the following sizes and specifications:

Standard and Grades: API 5CT J55 / K55, N80-1, N80Q, C90, T95, P110, Q125 and 13Cr

Casing Pipe Size range: 5 1/2” to 20” Length usually in R3.

Tubing Pipe dimensions range: 1.0”, 1.315”, 1.66”, 1.9”, 2.063”, 2 3/8”, 3 1/2”and 4 1 /2”, Length in R2.

Type of connections for Casing: BTC (thread coupling buttress), LTC (long round thread coupling), premium connection.

Types of connections for Tubing: BTC, NUE, EUE, Premium